Benefits

- Improve product visibility in food store applications as a result of the lighting being directed onto the food shelves rather than non-critical areas

- Reduce lighting-related energy consumption by up to 78% versus fluorescent bulbs

- Lower the heating load by up to 8% compared to a fluorescent bulbs

- Shorten compressor run time due to the reduced heating load

- 50,000 guaranteed run hours reduces maintenance costs versus fluorescent bulbs

- Lengthen compressor life as a result of reduced run times

Application and Savings

Historically, high-efficiency lighting has been one of the most popular and effective energy conservation measures, accounting for a large percentage of the overall savings that has been achieved. Indeed, as building owners converted from incandescent bulbs to T-12 fluorescents, then later to T-8 and T-5 fixtures with electronic ballasts, lighting-related energy usage has been greatly reduced.

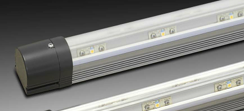

Despite the savings that has been achieved to date, LED lighting represent a quantum leap forward. In refrigerated display cases, LED lighting provides improved product visibility, reduced energy consumption and electrical demand, lower maintenance costs, and extended fixture life (upwards of 50,000 hours) when compared to incandescent and fluorescent bulbs. And since LED lights generate very little heat, the net cooling capacity of the display case is increased, compressor run time is reduced, and equipment life is extended.

LED lighting is also available for a wide variety of general applications. LED T-8 drop-in replacements provide savings of more than 50% over standard fluorescent bulbs. Screw-in replacement lights are presently being offered for MR16, Par 20, and Par 38 bulbs, while additional fixtures are coming into the marketplace most every day to satisfy a wide variety of lighting needs.