Benefits

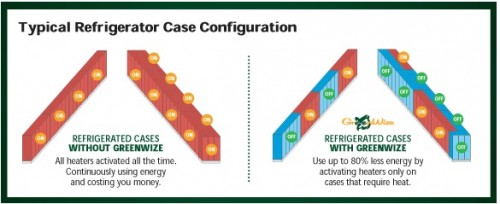

- Reduce energy usage (kWh) by cycling off heaters when they are not needed

- Decrease electrical demand (kW), particularly during cold winter months

- Minimize the heat added to the case by reducing heater run time

- Extend compressor life by reducing the load on the case

Operation and Savings

Most glass doors on refrigerated cases are equipped with anti-sweat heaters to prevent the formation of moisture on the glass when the indoor relative humidity is too high (usually above 60%). While the anti-sweat heaters have been quite effective at the intended purpose, which is to prevent the doors from fogging up, they consume as much as $200 per door per year in energy costs. That is because in the absence of controls, the heaters are set to run 24 hours per day, 365 days per year.

Anti-sweat heater controls can reduce heater run time by upwards of 70%, depending on indoor air conditions. This reduces energy use and demand, while lowering compressor run time by minimizing the heat being added to the cases. As such, anti-sweat heater controls are among the most cost-effective energy conservation measures at the disposal of food store operators.